This story first appeared in the January-February 2016 issue of Soybean Business, the magazine of the Minnesota Soybean Growers Association. Click here to read more articles from Soybean Business

Biodiesel plays an important role in ambitious NYC plan

Mitch Lappin knows the boiler in his building. As the building engineer, he is the person responsible for making sure the 1979 burner keeps the tenants of the Natural Resources Defense Council (NRDC) office in New York City warm.

So when Facilities Manager Milly Suarez explained to Lappin that Anthony Guerrero, Director of Facilities and Administration, had a plan to make the New York office a net-zero building and they wanted to use biodiesel in the heating oil, he had apprehensions.

“Mitch’s concerns were how this was going to affect the mechanical system,” she told a group of soybean farmers and biodiesel experts during the National Biodiesel Board Bioheat Tour in December at the New Jersey and New York Port Authority. “That’s his baby. The building is his baby.”

Lappin admitted the move to B100 has come with a few surprises, though not the ones he’d expected.

“At the inception of the project, my concerns were the transition from standard two diesel to bio,” he said.

Lappin met with their fuel supplier, Tri-State Biodiesel, and talked through the process. He wondered whether or not his boiler would need modifications in order to burn biodiesel.

“I got ‘you should be fine’ from the oil supplier and my combustion team,” he said. “I wasn’t exactly comfortable with that.”

Lappin brought in a company to clean and steam thesuction lines and valves from the tank to the burner. He then mixed 1,000 gallons of No. 2 diesel with 1,000 gallons of biodiesel to “wean the machine off standard diesel.”

“I was surprised because it was flawless,” he said. “The transition was smooth. So that answered my questions.”

Additional testing helped confirm his faith in the new product. During the yearly startup test for the boiler, the differences were staggering.

“The obvious difference was zero fumes in the basement,” he said. “There’s no smell, which makes my life easier. No residual, no nothing.”

That was only the tip of the iceberg.

“The maintenance on the boiler became fantastic,” he said. “I started to track it and in recent years we went from 12-15 pounds of carbon soot to two.”

To further test the difference between standard diesel and biodiesel, Lappin conducted a new test this past fall during the yearly startup test. He again brought in a company to clean out the tubes and extract whatever residual was left over from the past winter.

“The guy was like, ‘Mitch, I don’t see much,” he said. On further inspection, they had their answer. “We went from I’d say three, 55-gallon garbage bags of carbon soot, not quite full but several inches high, to almost nothing this year. Maybe two pounds or a pound and a half. It was amazing.”

There is a noticeable difference in burning efficiency as well, Lappin said. With No. 2 diesel, the NRDC boiler had an 86 percent efficiency rating when burned on a low flame, and an 87 percent efficiency rating when burned on a high flame. With biodiesel, the burner has a 90 percent efficiency rating on the low flame and a 93 percent efficiency rating on the high flame.

Also during this year’s startup test, his combustion team was worried about the smoke stack temperatures. Lappin recalled how a member of the team questioned the numbers from the test.

“Mitch, what’s the test results of your stack temperatures after they conducted the yearly startup tests,” the team member asked.

Lappin told him 138.6 degrees.

“He was like, ‘just check your numbers again,” Lappin said. “I said, it’s right here. I’m looking at the numbers on the computer printout you gave me and it is 136.8 degrees. What is the problem? He says, ‘I’m gonna be honest with you. Your machine couldn’t run any cleaner. What we look for is if you are anywhere in the area of 300 [degrees]. You’re fantastic.”

Ultimately, Lappin said biodiesel has made his life easier when it comes to dealing with the boiler at NRDC. He said he has become the envy of other building managers on the block who can’t believe the efficiency improvements he is recording from simply switching from standard diesel to biodiesel.

Sanitation Department keeps it clean

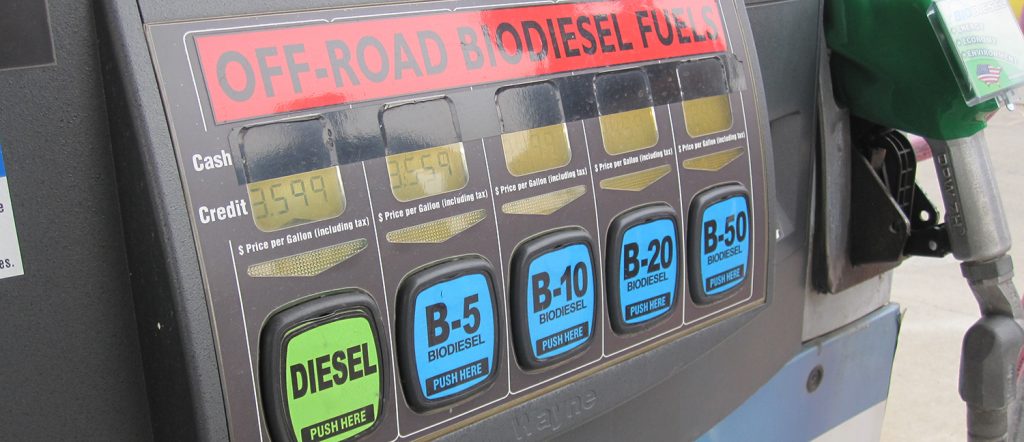

The New York Department of Sanitation (DSNY) is no stranger to using biodiesel in its fleet. City vehicles are required to run a blend of 5 percent biodiesel, or B5. But DSNY Deputy Commissioner Rocky DiRico said his department has run blends of B20 for years.

“We’ve had our obstacles along the way while pursing green,” he said. “We started using biodiesel eight or 10 years ago, and we’ve been pushing the move to B20 for a long time.”

DSNY has nearly 6,000 vehicles in its fleet, and while not all of them are diesel engines, roughly 3,000 run on biodiesel.

“I don’t know if there is a more simpler, more economically feasible way to cut our fossil fuels down,” he said.

Spiro Kattan, DSNY Supervisor of Mechanics of Clean Fuels & Technologies Division agrees.

“We went citywide with B5 In 2007, and today, from April to November, we are a B20 fleet and from December to March we are a B5 fleet,” he said. “We’ve displaced over 4 million gallons of fossil-based petro fuels, something we are very proud of, just by using biodiesel the past several years,”.

Impact on Minnesota

Minnesota Soybean Research & Promotion Council (MSR&PC) Vice Chairman Craig Bangasser attended the National Biodiesel Board Bioheat Tour to New York City to learn about NRDC and DSNY, as well as other agencies using biodiesel and Bioheat.

He came away impressed. Bangasser says it’s up to the Council to figure out how Minnesota can play a role in the growing biodiesel market in NYC.

“I think we need to look at all aspects of their plan,” he said. “While we know they want to increase the fuel standards for their city, I wonder if it is cost effective to source biodiesel from the Midwest. As MSR&PC directors, we need to look at this market, both for its use of biodiesel in city vehicles, in ferries and as a heating fuel, and figure out if there is a way we can have an impact. Is it a crush facility in the northern part of the state? Is it through the Port of Duluth? No one knows, but we’ll go to work as a Council and find out answers to these questions.”

Until then, Bangasser hopes New York’s efforts are noticed.

“The plan in place in New York is complex and looks at several ways to improve air quality,” he says. “But if they’re successful, hopefully other major cities will follow suit.”