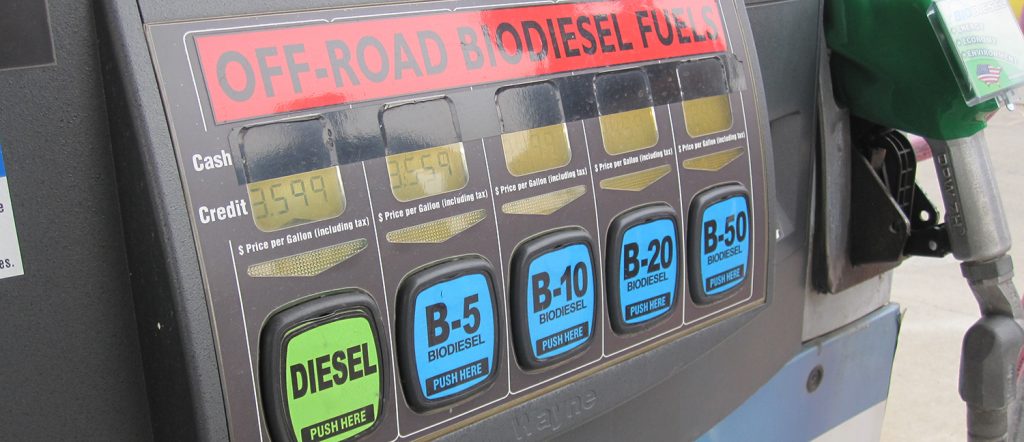

As we close out on a second successful summer of a B20 (20 percent) biodiesel blending requirement and now approach Oct.1, returning to a B5 (5 percent) biodiesel blending requirement for the winter months, there are many myths surrounding the use of biodiesel in cold temperatures.

Here are five common myths that need to be busted.

Myth: Minnesota requires B20 during cold winter months.

Fact: B20 is required in Minnesota’s No. 2 diesel fuel during the warm weather months. The minimum requirement during the cold weather months is only a 5 percent blend of biodiesel in No. 2 diesel. No. 1 diesel does not have a biodiesel requirement. During the coldest months of winter, No. 1 and No. 2 diesel are often blended in varying percentages to provide operability in these cold temperatures. This often results in biodiesel blends of only two to three percent.

Myth: Even low biodiesel blends, like 5 percent, lead to winter operability problems.

Fact: Biodiesel blends of B5 and lower are physically similar and perform the same as petroleum diesel fuel. In fact, the specification for petroleum diesel, ASTM D975, includes biodiesel blends up to 5 percent for on/off road engines. Whichever methods you use to winterize No. 2 diesel fuel, use the same strategy with biodiesel blends of B5 or lower. Minnesota’s No. 2 diesel fuel has contained 5 percent biodiesel in the winter since 2008.

Myth: Biodiesel causes bacterial growth.

Fact: Since the introduction of ultra-low sulfur diesel (ULSD) in 2006, microbial contamination has become a more common problem in diesel fuel. Before ULSD, higher sulfur levels acted as a natural antimicrobial. Bacteria and fungus grow in the water/fuel interface and can be present in both supply tanks and vehicle tanks, supply lines and fuel system components. This issue can be avoided by checking for water and removing it when it is found.

Myth: Biodiesel causes diesel to look milky and thicken during freezing cold temperatures.

Fact: Paraffin is a naturally occurring material in petroleum diesel fuel. The “cloud point” of diesel refers to the temperature when the first wax crystals appear. When the temperature of the fuel is at or below its cloud point, more paraffin appears, sticks together forming bigger compounds and falls to the bottom of the tank. Wax Anti-Settling Agent additives are used to keep paraffin from attaching to each other and suspended in the fuel rather than collecting at the bottom of the tank where they can cause filter plugging.

Myth: Biodiesel causes filter plugging in cold temperatures.

Fact: Diesel fuel requires special handling in cold weather. There are many factors that will cause filter plugging in the winter.

- When air temperature gets below 32°F, water freezes. If you have water in your fuel system you can seeing icing problems below 32°F.

Tip: Avoid water absorbing filters. They collect water and will freeze when temperatures are below the freezing point of water.

- Typical Minnesota diesel has a cloud point of 0°F to 10°F. In order for diesel to operate below these temperatures, diesel users must blend with No. 1 diesel and/or use diesel fuel additives.

Tip: Fuel additives must be added when the fuel temperature is at least 10 degrees above its cloud point to work.

- The colder the temperatures, the thicker diesel fuel gets. It doesn’t take much to restrict the flow through the fuel filter and any type of contamination will be more pronounced in winter – water, sediment, oxidation can lead to filter plugging.

Tip: Install a new fuel filter going into winter.

Contact the Minnesota Diesel Helpline with biodiesel questions or diesel fuel or filter issues: (800) 929-3437