As Public Works manager for the City of Hutchinson, John Olson is accustomed to hearing pitches on the next great product in road maintenance and repair.

Thus, he admits he initially wasn’t a true believer in a new biobased road sealant and rejuvenator.

“I didn’t know squat about RePlay. A little skeptical,” Olson confessed at a Biobased Road Sealant and Road Improvement Update meeting hosted by the Agricultural Utilization Research Institute (AURI) at the City of Hutchinson’s Public Works building. “In this business, it seems like everybody has the be-all, end-all, fix-all.”

Olson greeted the group of legislative representatives and agency representatives by sharing how, in 2010, the City of Hutchinson, along with McLeod County, worked with Mountain Lake-based Bargen Inc. to apply for a grant through the Minnesota Local Road Research Board’s Local Operational Research Assistance Program (OPERA).

“That really was a way for me to proceed with a project like this, to try it out, not have to spend a lot of tax payer money on it,” Olson says.

Olson regaled the crowd with the early research discoveries, like the pavement’s ability to shed water quickly when treated with RePlay, or how the product glues the top inch of pavement together.

In all, Olson, who oversees 76 miles of city roads, now regularly uses RePlay in his road maintenance program, but not as a be-all, end-all, fix-all solution.

“Keeping good streets in good conditions is the least expensive thing to do,” Olson says. “Fixing streets that are starting to get in worse condition becomes a lot more expensive per square yard.”

A checkoff relationship

Each year, the United Soybean Board and state soybean checkoffs invest in new uses for soybeans. Often times, those products pass through the research and development phase and become an afterthought because there are many barriers to taking a research concept and making it a commercially successful product that can compete against traditional products that are often made with foreign oil.

“Our farmer leaders have been very vocal about making sure that investments are more than developing products but also making sure that those products find a market,” says Mike Youngerberg, Minnesota Soybean’s senior director of product development & commercialization. “Even a niche market helps increase the use of soybeans, and that’s important for Minnesota farmers.”

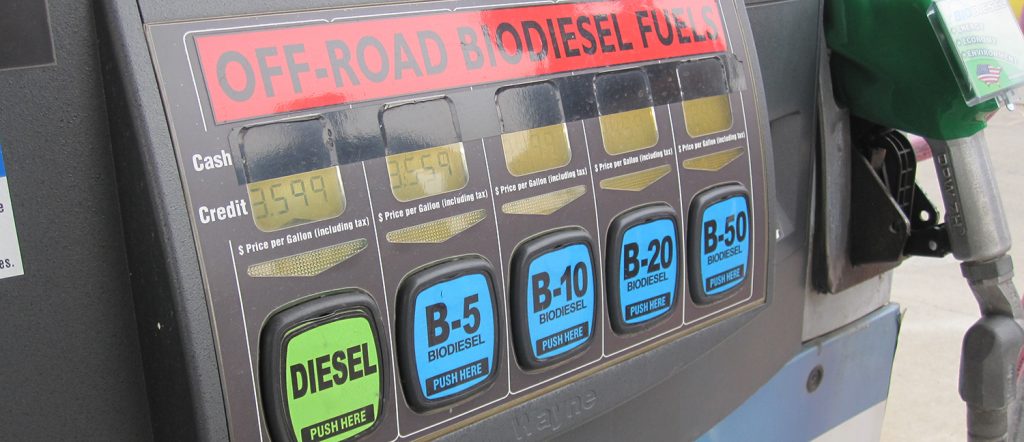

The difference with products such as RePLAY is that the asphalt market holds a lot of potential for soybean producers. According to the National Asphalt Pavement Association (NAPA), there are approximately 18 billion tons of asphalt pavement in the U.S., with more than 2.6 million miles of paved roads, 93 percent of which are paved with asphalt.

“It takes soybean oil from roughly 100 bushels of soybeans to maintain one lane-mile with RePLAY,” Youngerberg says. “So for every mile we are looking at roughly 200 bushels of soybeans, and we have more than 2.4 million miles of asphalt roads in the country. That’s a lot of miles and a lot of soybeans.”

MSR&PC District 7 Director Jim Willers chairs the Council’s new uses action team. He points to a long relationship with AURI as a key part of promoting RePLAY and other similar products.

“AURI is a very valuable partner when it comes to investing soybean checkoff money into developing new uses for soybeans,” Willers says. “We also believe that AURI can help bring a third-party, science-based credibility to the table when it comes to promoting the use of products.”

Willers says products such as RePLAY have allowed the Council to shift its thinking on how to invest checkoff money.

“We’re looking for fresh opportunities for soybean products already on the market,” he says. “As directors, it’s our responsibility to look beyond only developing a product and push toward adoption of the soy products in the marketplace.”

Seal coat with attitude

For the City of Hutchinson, treating a roadway with RePlay cost $1.60 per square yard. While this can be more expensive than doing nothing, Olson says treating a road with RePlay once can push the need to seal coat a road out six to eight years. Further evidence, he says, suggests a second application could push the chip-sealing process out 12 to 16 years.

By comparison, seal coating a road in Hutchinson costs $13 a square yard. A structural overlay costs $30 a square yard, a full-depth reclamation is $31 per square yard. When roads need a partial reconstruction ($75/sq yard) or a full reconstruction ($144/sq yard), the cost of doing business is astronomical.

Dr. Shel Chesky, the founder of BioSpan Technologies, which holds the patent on RePlay, isn’t shy about bragging about his product, as attendees at the update meeting found out.

“RePlay is a seal coat with an attitude,” he says.

Chesky points to RePlay as just one of many innovative products his company has discovered using biobased materials.

“We took the soybean and we squeezed out its innards and we worked with the oil to create 23 new soybean solvents, all patented, that will replace the petroleum products they were created to displace, and to do it much better,” he says. “The best part is, it is safe for you and I.”

Olson pointed to a situation in Hutchinson that, as he says, really highlights how well RePlay works.

“Like oodles and oodles of other communities in the area, we had severe frost damage this year. Worst we’ve ever seen,” he says. “We had roads blow apart. And when I say blow apart, the asphalt just disintegrated.”

One site Olson took attendees to was at the intersection of a new and old road, roughly eight years difference in age. When the new road was treated with RePlay, part of the old road was a recipient of the sealant as the sprayer turned around.

“Right here where I am standing is the same sub-base as what’s there,” Olson told attendees. “The difference between these two pieces is this was treated and this wasn’t. You can almost see the line where (the Bargen truck) would go.”