In soybean checkoff circles we talk a lot about “new uses” for all kinds of products that come from the soybeans that you grow every year. Since the Federal Soybean Checkoff came into existence in 1991, literally hundreds – if not thousands – of new uses for soybean products have come into existence.

Those new uses that we talk about today were not the priority they are today, as the industry was growing soybeans to feed a growing livestock industry with soybean meal and most all of the soybean oil was going to the food sector to feed our human demand, either domestically or internationally.

However, with the continued growth of soybean acreage around the world, over the years we found ourselves with excess of either the soybean protein or the soybean oil. These cycles were driven by demand, or lack of demand domestically or internationally. As an example, we used to export a lot of soybean oil to other countries, but with international trade agreements and domestic policies that were ever-changing, we found ourselves with lots of excess soybean oil that was truly dragging down the price farmer received for soybeans. This situation did not go unnoticed by either the new United Soybean Board (which was established in 1991) or by State Checkoff programs that had been in existence for many years prior to that.

So, the farmer leaders of these groups were determined to find other uses for your soybeans beyond those traditional uses (many of which still do exist), so they started an effort to work with public or private researchers to look at new ways to utilize the many parts of the soybean for new things outside the traditional uses.

Those prior and continuing investments are paying off in many ways for soybean farmers, helping to improve profitability.

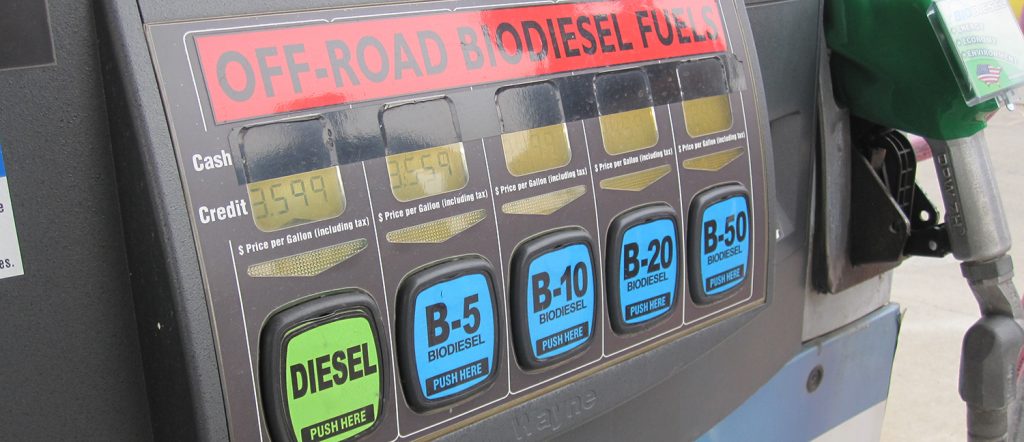

Probably the most notable of those new uses in biodiesel. In the late 1980s, the National Soy Diesel Development Board (NSDDB) was organized by a number of state checkoff leaders as a means to foster the research and development of soybased biodiesel. From those humble beginnings the U.S. biodiesel industry has grown from a mere 250,000 gallons of production in 2005 to more than 3 billion gallons today with anticipated growth, as estimated by the National Biodiesel Board (which replaced the NSDDB) to be exceed 6 billion gallons by 2030. Now, while soybean oil isn’t the only feedstock that can be used to product biodiesel, it is and will continue to be the dominate feedstock, with more 50% share of that market.

But also, out of that development of biodiesel we also saw a new line of other products developed off of the biodiesel platform. Products such as RePlay a soy-based asphalt and concrete sealant. Research right here in Minnesota has proven beyond a doubt that soy-based preservative products can extend the life of an asphalt road or street by up to 11 years while saving cities an estimated 30% in road maintenance costs. RePlay and similar new products continue to come to the marketplace, giving us all better roads and streets to drive on for longer.

From streets to roofs, we’ve now seen a similar technology being offered that can restore and preserve our asphalt roofs. Roof Maxx was another innovation driven by the soybean checkoff. It can save homeowners tons of money by preserving those roofs longer, thereby keeping more old shingles from ending up in landfills.

This is just one example of how the soybean checkoff has expanded our uses for soybean oil through the development of biodiesel many years ago.

So, we continue to build on biodiesel, which was “new” in the early 1990s, to things that are “newest” today, like the RoofMaxx product. There are hundreds of other products that have developed and can be found in the marketplace. You can check out more at www.soynewuses.org.

Mike Youngerberg is MSR&PC’s senior director of product development & commercialization. 2021 marks his 35th year with Minnesota Soybean.