It’s a hectic time of year for Minnesota soybean growers.

Before the temperature drops and the snow starts falling, there are a lot of tasks on their to-do lists to set them up for success the following year – including diesel tank maintenance.

And when it comes to getting diesel tanks – both storage and on machinery – winterized, the early bird gets the worm.

“Right now (in late September), we have beautiful temperatures that are in the 80s,” said Lisa Pedderson with MEG Corp. “Fast forward about a month from now, and the lows may be starting to get in the 20s.”

Tasked with wisely directing Minnesota soybean checkoff investments, the Minnesota Soybean Research & Promotion Council (MSR&PC) has partnered with MEG Corp to answer questions, solve problems and educate end users on proper use of biodiesel.

“Given what MEG Corp does for fuel distributors and for people having fuel problems, I actually think we have less problems in the state of Minnesota than other places,” said Mike Youngerberg, MSR&PC senior director of product development and commercialization.

A fuel industry leader in product solutions, testing services and fuel consulting, MEG Corp plays a vital role in Minnesota’s biodiesel industry. Here are a few tank maintenance tips for Minnesota producers as the fall season progresses:

- Remove water

Water may be essential to life but it’s not essential to diesel tanks. Before the thermometer hits 32 degrees Fahrenheit, removing water that has accumulated from condensation from diesel tanks is critical.

“There’ll be some people having problems with their dispenser filter when the temperature drops because the filter froze,” Pedderson said. “That’s probably because they have water in the bottom of their tank, and the filter does what it’s supposed to do – it filters that water out.”

- Fill tanks

Top off those fuel tanks to prevent problems down the road. When fuel tanks are kept full, fuel degradation from exposure to oxygen and moisture is reduced.

“It’s really important to keep tanks full so that you don’t have excess air,” Pedderson said. “When you’re done with harvest, fill everything up. A lot of farmers don’t like doing that because they view that as money that they don’t need to spend, but in order to not accumulate water, it’s recommended.”

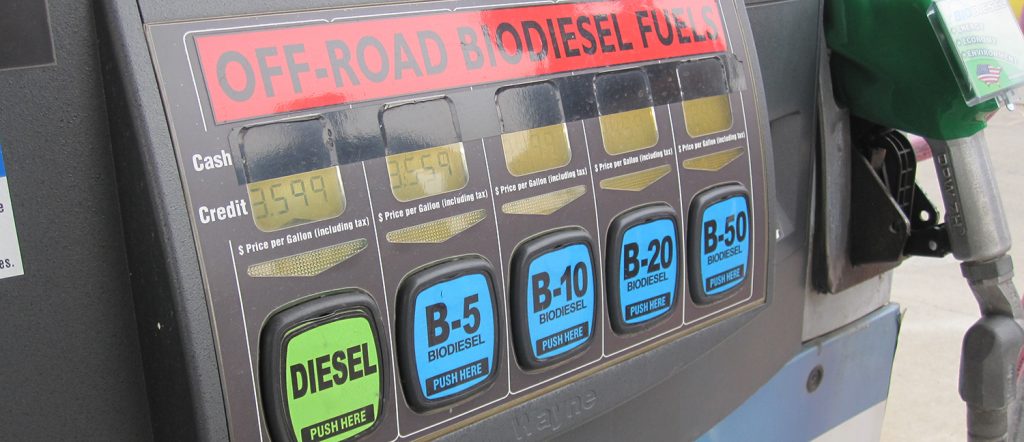

- Winter blends

The first state to pass a biodiesel mandate, Minnesota requires B20 (20 percent biodiesel) from April 16 to Sept. 30 and B10 from April 1-15. Starting Oct. 1, B5 is required through the winter months.

“The minimum blending requirements adjust to the seasons, so making the switch back to B5 ensures that we don’t have winter problems,” Youngerberg said.

With the beginning of October here, it’s time to start thinking about the transition.

“It’s really important to get your blend down to B5 before it gets too cold,” Pedderson said. “Five percent biodiesel is considered diesel fuel; the specification for number two diesel allows for up to five percent biodiesel. It’s going to operate exactly the same as B0.”

- Replace filter

Many farmers can replace filters in their sleep – fuel filters, oil filters, air filters, etc. But don’t forget about replacing the dispenser filters on diesel fuel tanks, especially when the weather changes. MEG Corp recommends installing a new 30-micron filter before harvest, or at the very least, before it gets cold.

“Fuel gets thicker as it gets colder and so it doesn’t go through the dispenser filter as easily,” Pedderson said. “We always recommend putting on a new 30-micron filter to handle the increased viscosity of the fuel.”

- Look everything over

Like any other piece of farm equipment, diesel tanks need to be examined consistently. To avoid downtime during harvest, MEG Corp encourages growers to look over their tanks to avoid hiccups during harvest.

“Make sure that caps are on tight, check gaskets and hoses and check places where there could be leaks,” Pedderson said. “That should be done regularly but the end of harvest is a good time to look everything over to make sure it’s in good operating order.”

For any fuel related questions or for help troubleshooting a fuel related problem, contact MEG Corp at the diesel helpline: 800-929-3437.